No Posts Found.

Deep learning is an advanced artificial intelligence technology that enables precise analysis of large datasets. It's used to automate complex tasks such as pattern recognition, forecasting, and decision-making. In industrial automation, deep learning powers machine vision, replicating human-level analysis to deliver superior results. Integrating deep learning into manufacturing processes enhances efficiency, reduces errors, and improves product quality.

Real-time data analysis to adjust machine speeds and reduce bottlenecks.

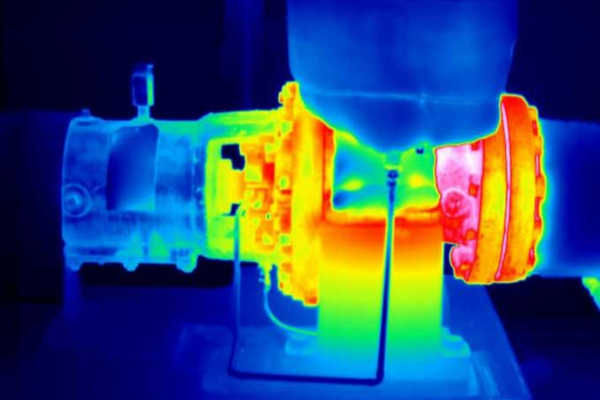

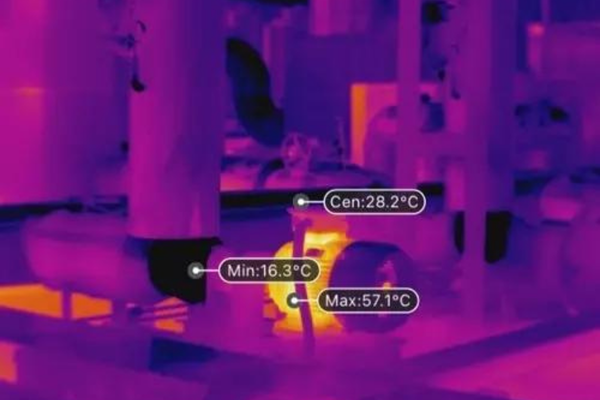

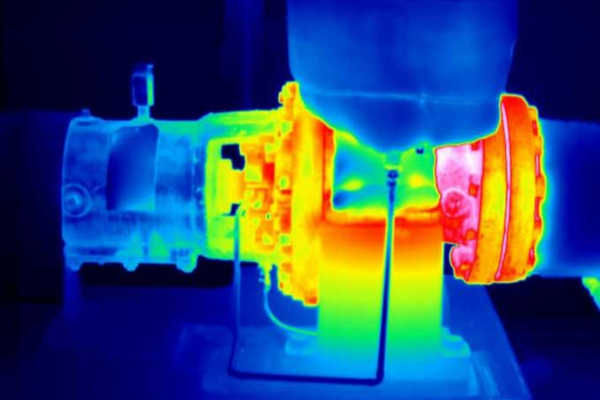

Using deep learning to predict equipment failures based on sensor data.

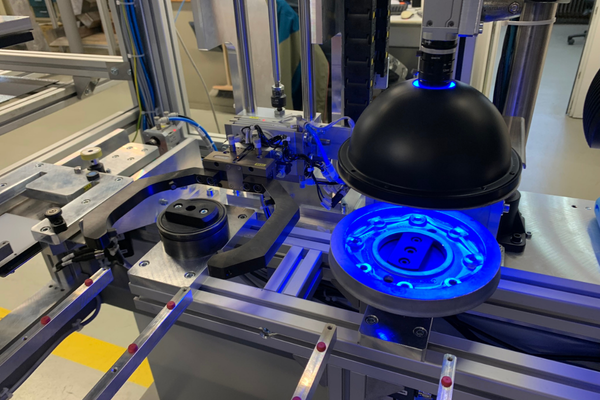

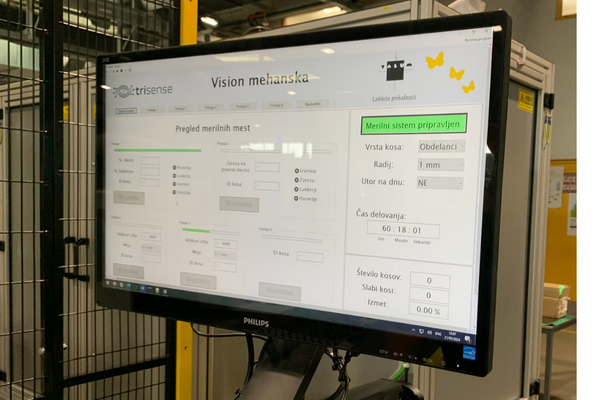

Automated inspection of finished products to detect defects like color or shape irregularities.

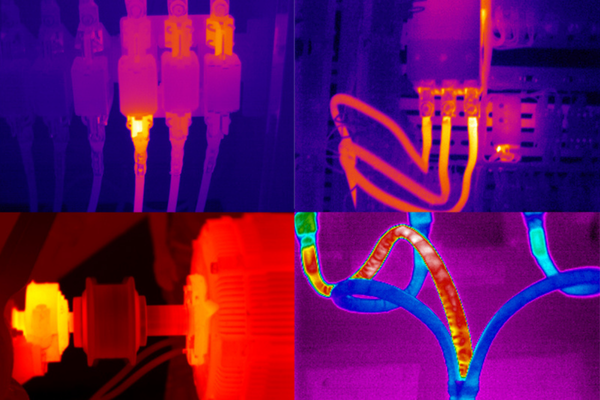

Edge vision combines the power of machine vision with edge computing, enabling rapid, local analysis of visual data. This technology reduces latency and enhances efficiency by processing data on-site, without the need for cloud transmission. Edge vision is ideal for applications requiring immediate decisions, such as real-time quality control, anomaly detection, and security monitoring.

Uporaba robnega vida za vodenje industrijskih robotov pri zapletenih nalogah.